The purpose of normalizing is to remove the internal stresses induced by heat treating welding casting forging forming or machining. As a result this metal is often mistaken for copper.

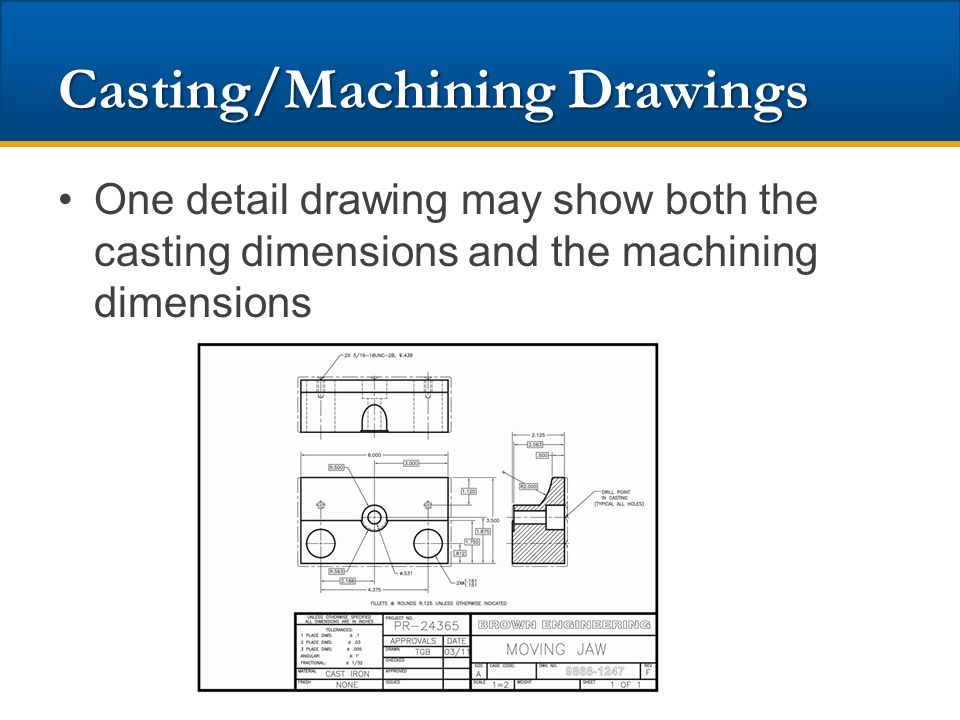

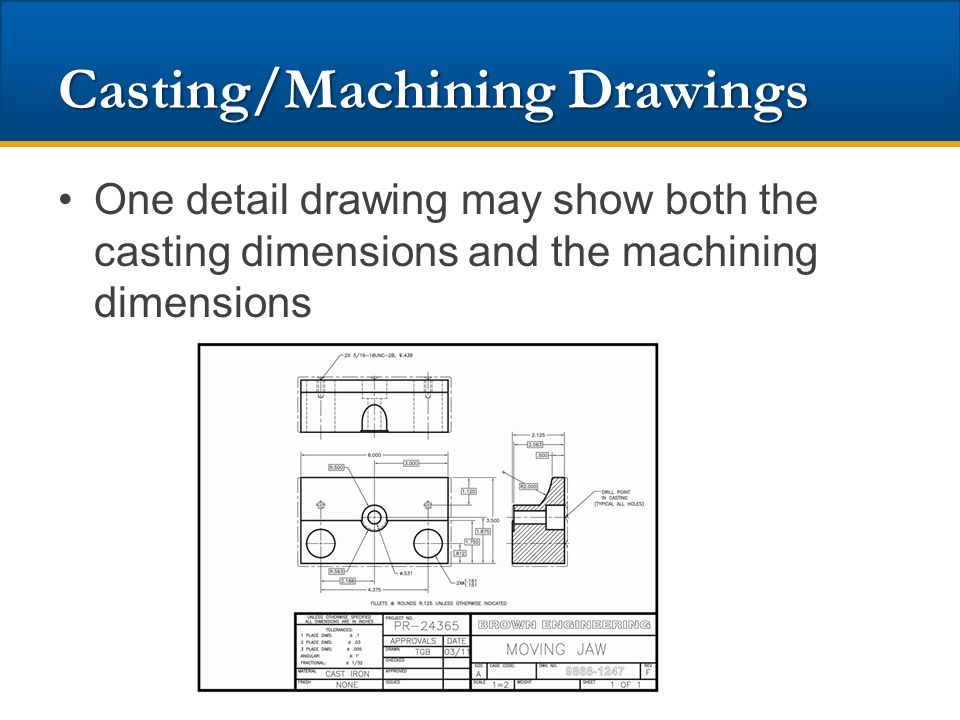

Module 3 Unit 15 Detail Drawings Ppt Video Online Download

Epoxy Casting Resin vs.

. When choosing between CNC machining and 3D printing there are a few simple guidelines that you can apply to the decision making process. I have 4 different sized drawing templates made one each for ABC and D size. This article describing investment casting is intended to help you make an informed casting decision.

Their unique benefits make each more suitable for different situations though. Investment casting produces precise components while minimizing material waste energy and subsequent machining. Brass is the name given to a copper alloy made up of certain zinc content.

Whether you are a designer engineer industrial design agency or a startup technology company Roche Industry is the perfect fit for your prototyping needs. In most cases coating epoxy resins are physically harder than casting resins. In addition to this brass is composed of other metals including tin iron aluminum lead silicon and manganese.

Forging is the process of deforming metal into a predetermined shape using certain tools and equipmentdeformation is accomplished. Casting resins regularly can change blend proportions which explain the difference in hardness. It differs from annealing in that the metal is heated to a higher temperature and then removed from the furnace for air cooling.

Without a drawing all CNC parts are produced to our ISO 2768 medium standard. There are times when I start a drawing on a C size bordersheet and it gets too cluttered as I add views or annotations. The hardness properties of cast iron demand careful selection of machine tool materials.

Most of the manufacturers have been adopted the 3D CAD if you are trying to choose a better option between 2D vs 3D CAD check out the difference between 2D and 3D CAD drawing well also get into the advantages of 3D CAD. Learn about the practical differences of CNC machining and 3D Printing and how to select the right technology for manufacturing end-use parts and functional prototypes. Hot forging and cold forging are two different metal forming processes that deliver similar results.

Both CNC machining and 3D printing are exceptional tools in the arsenal of an engineer. For the past many years Roche Industry provides on-demand manufacturing services using processes like 3D printing CNC machining vacuum casting injection molding and much more. If a CNC machining tool has a tolerance of 001 mm this means that the machining tool can have a deviation of 001 mm in every cut.

This makes the investment casting process quite useful to design engineers. The manufacturing of this steel type does not involve any delay or further processing. CAD files are commonly used in mechanical design and manufacturing which brings automation and innovation to lots of relevant industries.

Surface finishing of cast iron products varies greatly according to the use. The reason for this is not far-fetched. Written by Alkaios Bournias Varotsis.

Coated carbides are effective in production machining environments but newer materials are being developed continuously as technology improves. With a drawing Fictivs CNC machining service can produce CNC parts with tolerance as low as 00002 in. The best case of this is found in casting resin that is utilized as artificial water for a jar.

Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed instructions and without a. Is there any way to insertchange the sheet size to the D sized template without starting over. Hot Rolled vs Cold Rolled Steel.

It can also ensure the production of very intricate parts. Hot rolled steel is typically less expensive than cold rolled steel.

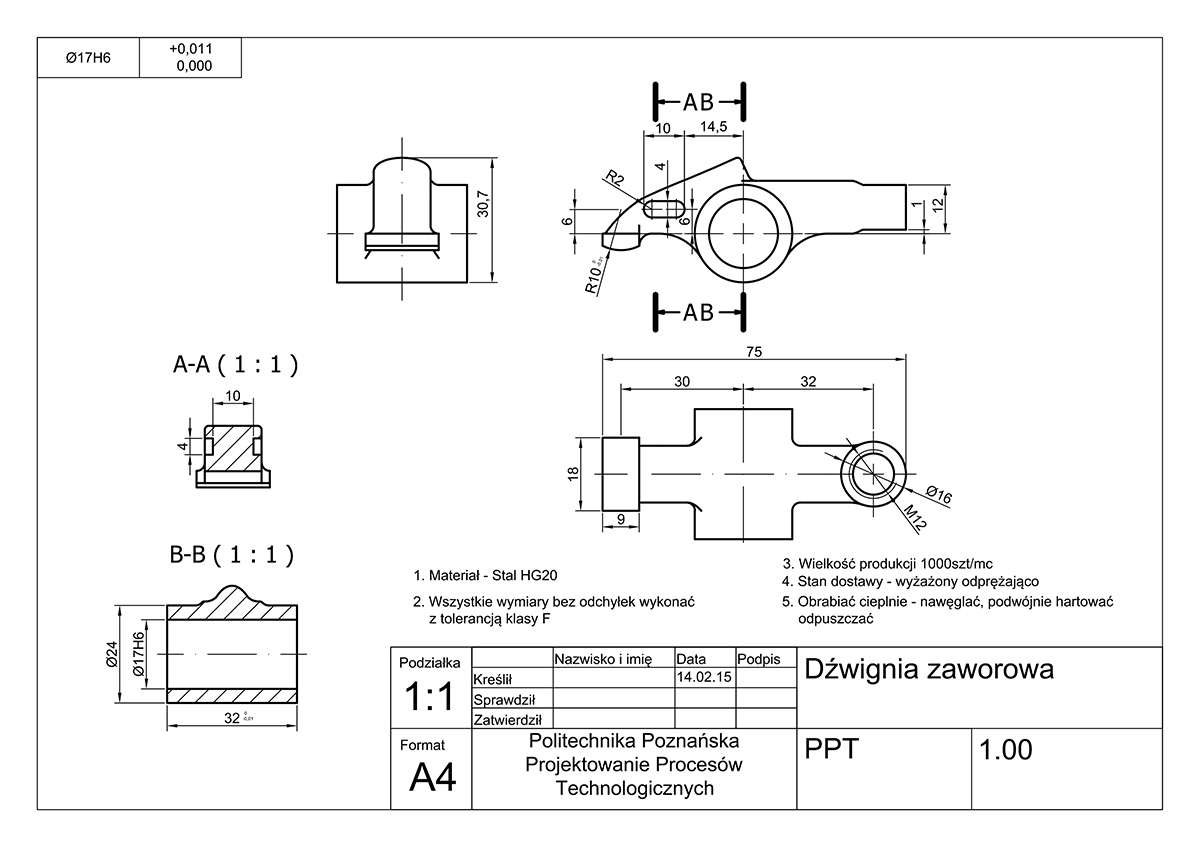

Solved Prepare Both The Casting And The Machining Drawings For The 1 Answer Transtutors

Solved 2 A Choose An Appropriate Casting Process Chegg Com

15 Detail Drawings Permission Granted To Reproduce For Educational Use Only Explain Terms And Standards Related To Various Types Of Drawings Used In Ppt Download

Creating A Machining Drawing For A Cast Part Youtube

0 comments

Post a Comment